A new wonder material has been

created from a surprisingly traditional source. Super wood is as robust

as steel and six times lighter. Scientists put the material through its

paces in ballistic tests and found that a specially laminated version

can stop a projectile in its tracks

Super wood that is as

robust as steel and six times lighter could be a renewable construction

material for the future, according to scientists.

Planks

of the reinforced lumber, which researchers have compared to

carbon-fibre, could be used to create anything from buildings and cars

to bullet proof jackets.

Scientists

put the material through its paces in ballistic tests and found that a

laminated version could even stop a projectile in its tracks.

Engineers at the

University of Maryland created their super dense wood by boiling blocks

of regular wood in a water-based solution, containing the

chemicals sodium hydroxide and sodium sulfite.

This process removed organic compounds in the wood that give its structure and rigidity, making it more pliable.

It is similar to the initial stages of treating wood to create paper.

The

team then pressed the softened wood between two metal plates, heated to

100°C (212°F), at 50 times the atmospheric pressure of the Earth.

By doing so, all of the gaps between cells in the wood were squeezed together.

The pressure creates a chemical bond between the atoms that make up the wood's cellular structure.

It shrunk the size of the block to around one fifth of its original thickness, increasing its density by 300 per cent.

Super Wood Could Replace Steel https://t.co/pib0NnRzjF pic.twitter.com/sggPICLiv8— ScienceDaily (@ScienceDaily) February 9, 2018

Stronger than steel, able to stop a speeding bullet—it’s super wood! https://t.co/oxH8EUEiJL pic.twitter.com/vMNZcQnILg— Scientific American (@sciam) February 7, 2018

Liangbing

Hu, who led the research, said: 'This new way to treat wood makes it 12

times stronger than natural wood and ten times tougher.

'This could be a competitor to steel or even titanium alloys, it is so strong and durable.

'It's also comparable to carbon fiber, but much less expensive.

The team tested the new wood material and natural wood by shooting bullet-like projectiles at it.

Engineers at the University of

Maryland created their super wood by boiling blocks of regular wood in a

water-based solution containing the chemicals sodium hydroxide and

sodium sulfite

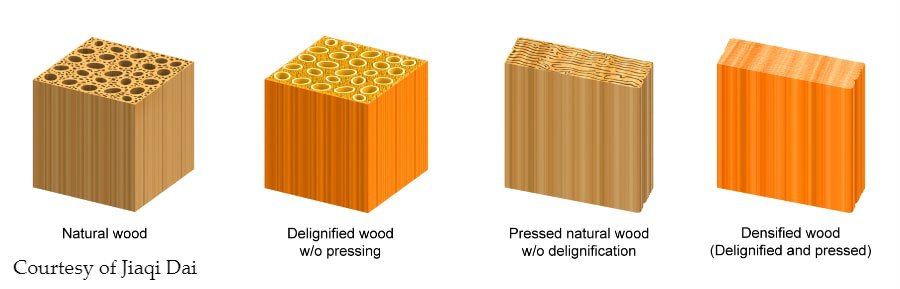

This process removed organic

compounds in the wood that give its structure and rigidity, making it

more pliable. This image shows the treatment process used

The

projectile blew straight through the natural wood, while a single layer

of the treated wood slowed the projectile's progress.

A

third laminated version, consisting of layers of five-layers of the

densified wood, was penetrated by the projectile but stopped it

from exiting.

Dr Hu's research team has explored the capacities of wood's natural nanotechnology in the past.

They have previously made a range of technologies out of nanocellulose related materials.

This

has included super clear paper for replacing plastic, photonic paper

for improving solar cell efficiency by 30 per cent and transparent wood

for energy efficient buildings.

The full findings of the latest study were published in the journal Nature.

The pressure creates a chemical

bond between the atoms that make up the wood's cellular structure. It

shrunk the size of the block to around one fifth of its original

thickness, increasing its density by 300 per cent. This image shows the

changes in the various wood samples

The team tested

the new wood material and natural wood by shooting bullet-like

projectiles at it. This image shows the results of those tests

WHAT IS THE STRONGEST MAN-MADE MATERIAL?

For years, researchers have known that carbon, when arranged in a certain way, can be very strong.Two man-made materials based on carbon, Graphene and Carbyne, are among the strongest in the world.Carbyne is linear acetylenic carbon, or an infinitely long carbon chain.Its existence was first proposed in 1885 by Adolf von Baeyer, who warned it would remain elusive due to extreme instability.Carbyne is a one-dimensional form of carbon and is thought to be 40 times stiffer than diamond and twice as stiff as graphene, outperforming all other carbon materials in strength.After eluding scientists for more than 50 years, a team of researchers found a way to not only synthesize carbyne, but to mass produce it, in April 2016.Graphene, a single atomic layer of carbon atoms bound in a hexagonal network, was previously thought to be the strongest man-made substance.It not only promises to revolutionize semiconductor, sensor, and display technology, but could also lead to breakthroughs in fundamental quantum physics research.It is often depicted as an atomic-scale chicken wire made of carbon atoms and their bonds.

Graphene, the world’s strongest material, is a million times thinner than paper but 200 times stronger than steel. pic.twitter.com/E2CojwHFWY— World and Science (@WorldAndScience) February 4, 2018

Water-soluble warped nanographene - Graphene and its nano-sized little sibling, nanographene, are well known for their remarkable photoelectronic properties. However, biomedical applications are hampered by the insolubility of the materials, especiall... https://t.co/Rb2lXJiVDT— Arun Swamy (@Gemini_72) February 9, 2018

Scientists believe it could one day be used to make transparent conducting materials, biomedical sensors and even extremely light, yet strong, aircraft of the future.Similar to another important nanomaterial - carbon nanotubes - graphene is incredibly strong - around 200 times stronger than structural steel.While notable for its thinness and unique electrical properties, it’s very difficult to create useful, three-dimensional materials out of graphene.In January, 2017, a team of MIT researchers discovered that taking small flakes of graphene and fusing them following a mesh-like structure not only retains the material’s strength, but the graphene also remains porous.Based on experiments conducted on 3D printed models, they determined that this new material can be used to make objects 10 times stronger than steel, with only five per cent of its density.

Post a Comment Blogger Facebook Disqus